Genuine energy efficiency, precise temperature control and measurable return for demanding businesses

In 2026, commercial refrigeration is no longer purchased solely for capacity or design. It is purchased for profitability.

The HORECA and retail sectors are operating under constant pressure:

- Rising energy costs

- Stricter environmental regulations

- The need to optimise every pound invested

“Do I need to replace my equipment?” is no longer the right question. The real question is: How much am I losing by continuing to operate with traditional technology?

This is where Inverter technology makes the difference. It has become a high-impact lever for professional refrigeration equipment. This is not a passing trend, but a technological advancement that redefines the relationship between performance, consumption and operating costs for demanding businesses.

What is Inverter technology in commercial refrigeration?

Inverter technology allows the compressor to operate at variable speed, adjusting its output according to the actual thermal demand of the equipment. Unlike traditional systems, which operate through constant start–stop cycles, an Inverter system maintains continuous, modulated operation. The result?

- Lower energy consumption

- Greater temperature stability

- Reduced mechanical wear

This is not an incremental improvement. It is a structural shift in how energy is managed in professional refrigeration equipment.

Inverter technology vs traditional systems: key differences

| Traditional system | Inverter technology |

|---|---|

| Constant start–stop cycles | Continuous, modulated operation |

| Energy consumption peaks | Consumption optimised to demand |

| Greater compressor wear | Reduced mechanical stress |

| Temperature fluctuations | Stable, controlled temperature |

In environments such as professional kitchens, supermarkets or food service establishments, this difference translates into something tangible: Real cost savings and reduced operational risk.

Benefits of Inverter technology in professional refrigeration equipment

1. Energy savings of up to 40%

The main advantage of an Inverter system is reduced energy consumption. By eliminating start-up peaks and adjusting output to actual load, equipment equipped with Inverter technology can reduce energy consumption by up to 40% compared with conventional systems. In businesses where refrigeration operates 24/7, this directly impacts:

- Operating costs

- Profit margins

- Return on investment

It is not simply efficiency. It is competitiveness.

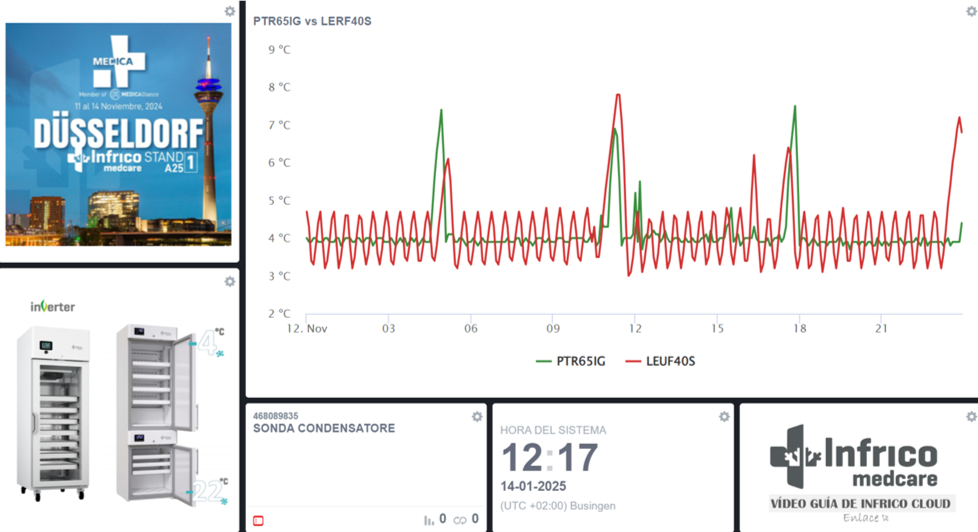

2. Thermal stability and product protection

Temperature fluctuations directly affect the preservation of food and beverages. Efficient commercial refrigeration must guarantee:

- Consistent temperature control

- Maintenance of the cold chain

- Reduction of product waste

In display cabinets, refrigerated cabinets or refrigerated counters, stability is not a minor technical detail: it is margin protection.

3. Longer service life and reduced maintenance

Smooth, continuous operation reduces compressor stress. This leads to:

- Fewer unexpected breakdowns

- Lower maintenance costs

- Greater equipment durability

For a professional business, fewer incidents mean fewer disruptions. And fewer disruptions mean greater revenue stability.

4. Performance adapted to real business demand

In a restaurant or supermarket, thermal load changes constantly:

- Doors opening

- Peak service hours

- Product restocking

Inverter technology automatically responds to these variations, optimising performance without manual intervention. Intelligence applied to commercial refrigeration.

Inverter technology in Infrico commercial refrigeration equipment

In an environment where efficiency and return on investment determine purchasing decisions, Infrico combines its leadership in commercial refrigeration with the most advanced technologies available, including solutions based on high-performance Inverter compressors integrated into its latest ranges of refrigerated cabinets and undercounters.

Beyond this core technology, Infrico continuously develops energy-efficient and environmentally responsible solutions, including systems using natural refrigerants and advanced condenser circuit configurations designed to anticipate the most demanding regulations and global market expectations.

This commitment to efficiency, sustainability and performance forms part of a broader vision of continuous innovation, meeting the needs of the HORECA, retail and food service sectors — where every investment must deliver proven, long-term and measurable performance.

Is investing in commercial refrigeration with Inverter technology worthwhile?

The short answer: yes. The strategic answer: it depends on how long you are willing to continue overpaying on your energy bill. When equipment operates 365 days a year, every percentage improvement in efficiency has a cumulative impact. Investing in Inverter technology is not a technical decision. It is a financial one.

Inverter: a strategic and measurable investment

Inverter technology has moved from being an optional feature to becoming a key differentiating factor in professional refrigeration.

In a market defined by sustained energy cost pressure, skilled labour shortages and the need to comply with increasingly strict sustainability regulations, Inverter technology enables:

- Genuine reductions in energy consumption and operating costs

- Improved product preservation through consistent temperature control

- Greater equipment reliability and durability

- Measurable medium- and long-term return on investment

For industry decision-makers, investing in equipment with Inverter technology is not simply about embracing efficiency.

It is about acquiring solutions that respond to the competitive and regulatory realities of 2026.

Discover Infrico’s commercial refrigeration solutions with Inverter technology and calculate the real savings for your business.

Communication

Communication